The Porcelain Tile Manufacturing Process: From Clay to Beautiful Flooring

Porcelain tile is a popular choice for homeowners and designers due to its durability, versatility, and aesthetic appeal. But have you ever wondered how porcelain tiles are made? In this blog, we will take a closer look at the porcelain tile manufacturing process, from the initial stages of clay preparation to the final firing and glazing, to understand the intricate steps involved in creating these beautiful and functional flooring materials.

Clay Preparation:

The manufacturing process begins with the careful selection and preparation of high-quality clay. The clay is mined from quarries and undergoes a series of processes to remove impurities and achieve the desired consistency. It is then mixed with water to create a clay slurry, which will serve as the base material for the porcelain tiles.

Shaping and Drying:

Once the clay slurry is ready, it is poured into molds or pressed using hydraulic presses to give the tiles their desired shape and size. The excess water is then removed through a drying process, either by air-drying or using specialized drying chambers. This step is crucial to ensure the tiles maintain their shape and prevent warping during firing.

Firing:

The dried tiles are placed in kilns and subjected to high temperatures, typically ranging from 1200 to 1400 degrees Celsius. This firing process transforms the clay into a dense and hard material, making it highly durable and resistant to water absorption. The firing time and temperature may vary depending on the desired characteristics of the porcelain tiles, such as color, texture, and strength.

Glazing:

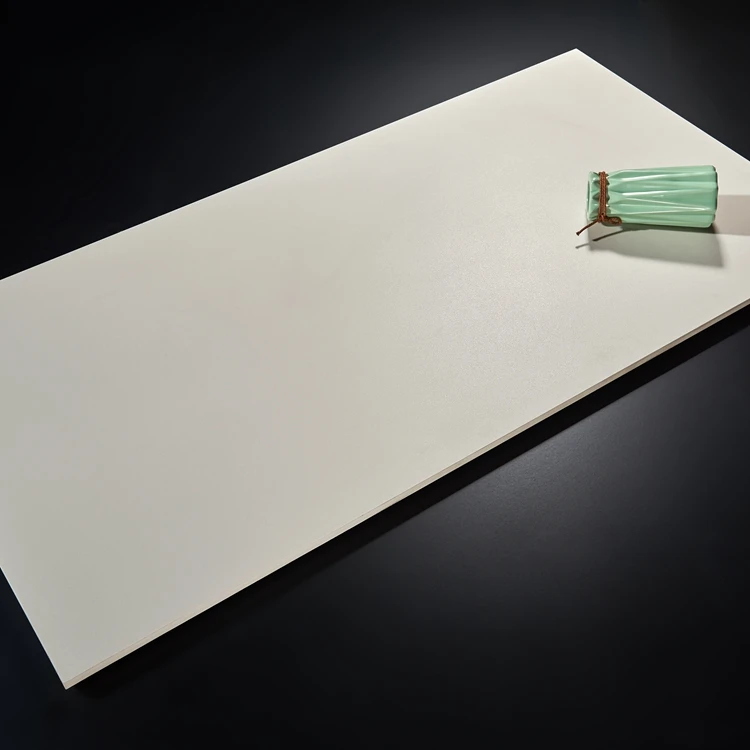

After the initial firing, some porcelain tiles undergo a glazing process to enhance their appearance and provide additional protection. Glaze, a liquid mixture of minerals and pigments, is applied to the surface of the tiles. The tiles are then fired again at lower temperatures to fuse the glaze onto the surface, creating a smooth and glossy finish. Glazing also adds color and design variations, allowing for endless possibilities in tile aesthetics.

Quality Control and Packaging:

Once the tiles have been glazed and fired, they undergo rigorous quality control inspections to ensure they meet industry standards. This includes checking for any defects, such as cracks, chips, or inconsistencies in color and size. Tiles that pass the quality control tests are carefully packaged and prepared for distribution, ready to be shipped to retailers or directly to customers.

Conclusion:

The porcelain tile manufacturing process is a complex and intricate journey from raw clay to the final product. Each step, from clay preparation to firing and glazing, requires precision and expertise to create high-quality and visually appealing tiles. Understanding the manufacturing process not only deepens our appreciation for the craftsmanship behind porcelain tiles but also helps us make informed decisions when selecting the perfect flooring option for our homes or commercial spaces.